In modern industries, drives and servo drives are the beating heart of automation. From powering production lines to ensuring precise motion control, they play a critical role in keeping operations efficient. But like any high-performance equipment, they are prone to failures especially when running in tough environments with 24/7 demand.

At Automat, we’ve seen it all. As the largest multi-brand industrial repair center in the region, we specialize in diagnosing and fixing drive and servo drive issues with precision. In this blog, we’ll walk you through the top 5 failures in drives and servo drives, why they happen, and how we bring them back to life.

1. Power Supply Failure

The Problem

One of the most common issues in drives and servo drives is power supply failure. Fluctuations in input voltage, blown capacitors, or faulty rectifiers can cause the drive to fail, shutting down production lines unexpectedly.

Why It Happens

- Poor power quality or unstable grid supply

- Overvoltage or undervoltage

- Aged capacitors and internal components

How Automat Fixes It

Our engineers use advanced testing benches to diagnose power circuit issues. We replace faulty capacitors, rectifiers, and regulators with OEM-grade components. Once repaired, each unit undergoes load testing to ensure it can handle real-world conditions reliably.

2. Overheating and Cooling System Failure

The Problem

Drives and servo drives generate significant heat during operation. If their cooling fans, heatsinks, or thermal management systems fail, overheating can quickly damage sensitive electronics.

Why It Happens

- Dust and dirt clogging cooling fans

- Blocked air vents in industrial environments

- Failed cooling fans or thermal sensors

How Automat Fixes It

We clean, replace, and recalibrate the entire cooling system. Our service includes installing new fans, checking thermal sensors, and ensuring airflow is optimal. Preventive cleaning and thermal audits are also offered to reduce future risks.

3. Communication & Encoder Failures

The Problem

Servo drives rely heavily on communication signals and feedback systems like encoders and resolvers. When these systems fail, positioning accuracy suffers, leading to misalignment, jerks, or complete breakdown.

Why It Happens

- Damaged encoder cables or connectors

- Faulty feedback devices (resolvers, tacho, hall sensors)

- Interference in signal transmission

How Automat Fixes It

Our encoder alignment and signal correction process ensures feedback loops are restored to factory standards. We repair or replace damaged encoders and feedback systems, test alignment angles, and eliminate signal distortions.

4. Control Board & IGBT Module Failures

The Problem

The control board and IGBT (Insulated Gate Bipolar Transistor) module are the “brains” of the drive. If they fail, the drive loses its ability to regulate motor speed or torque, often triggering error codes or total shutdown.

Why It Happens

- Power surges and voltage spikes

- Excessive load or short circuits

- Wear and tear of semiconductor devices

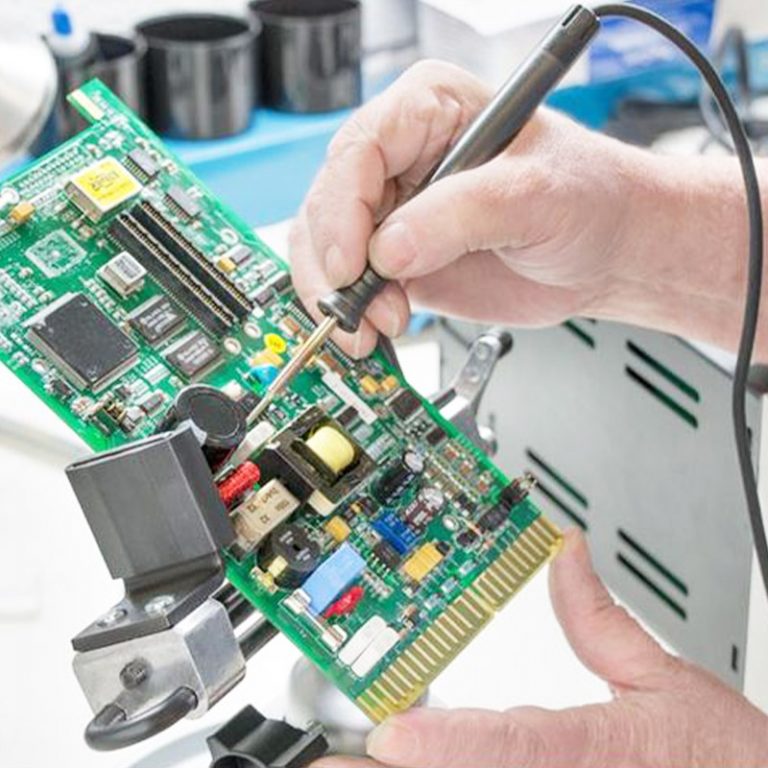

How Automat Fixes It

Our repair process includes microscopic inspection and chip-level repair of control boards. IGBTs are tested under real load conditions, and faulty modules are replaced with genuine, high-performance parts. Every repaired board undergoes software reprogramming and calibration to restore OEM-grade performance.

5. Mechanical Wear & Tear in Servo Motors

The Problem

Though electronic failures are common, servo motors connected to drives also suffer mechanical issues. Bearing failures, shaft misalignment, or vibration problems can cause inefficiency and system errors.

Why It Happens

- Continuous heavy load

- Lack of lubrication

- Natural mechanical degradation

How Automat Fixes It

Our servo motor repair services cover complete overhauls, including:

- Bearing replacement with high-radial load types

- Shaft inspection and correction

- Motor vibration diagnostics

- Encoder/feedback system realignment

- Sandblasting and external refurbishment

This ensures the motor works as good as new with extended service life.

Why Choose Automat for Drive & Servo Drive Repairs?

Right repair at the right time!

Drives and servo drives may fail for many reasons, but every failure doesn’t need a costly replacement. With the right repair at the right time, you can save significant costs, extend equipment life, and keep your operations running smoothly.

At Automat, we don’t just repair, we revive.

Because in automation, uptime is everything.