Which one do you choose?

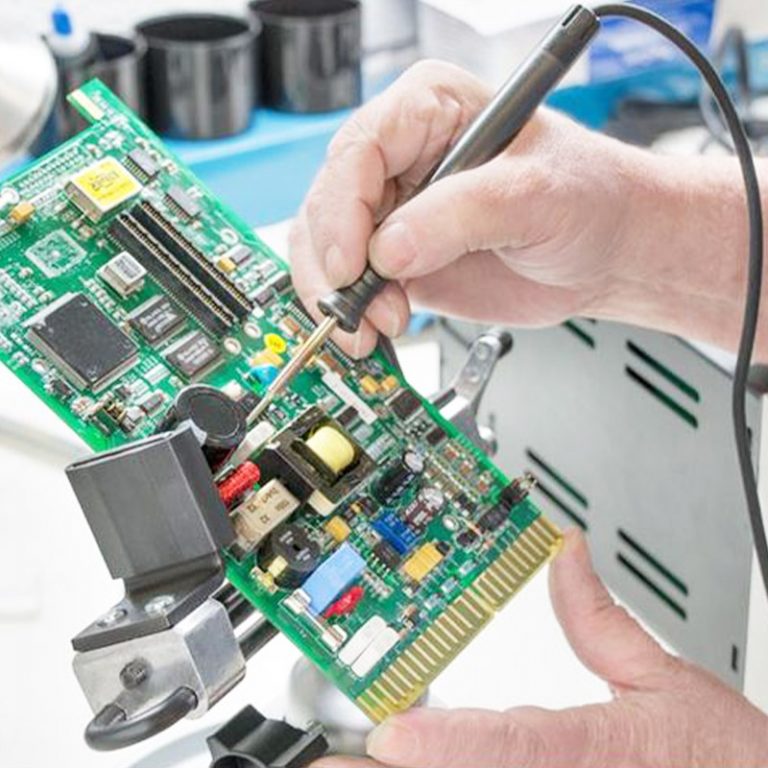

A local manufacturer or foreign manufacturer for your PCB repair services? Let’s see in detail. It is an unavoidable fact that the market has a shortage of semiconductors. Thus it is taking much longer to get PCB repaired. Some equipment must be repaired completely or else it must be done at component level. A local manufacturing service center can fix all these issues as they will be aware of repairing it even at a component level. These can be extremely cost-effective, and add significant value to local manufacturing choices.

Also, post-sale support is one of the most costly areas of any electronics production, and it’s done right when you approach a local manufacturer. Any savings in this area will only help your bottom line, and potentially help customer retention as well.

What should you enquire about as a PCB repair service provider?

Call Centers that works online

Have you ever thought about the employees who attend your calls and answer all the queries? Sometimes the customers never cared that they are a part of the company. So the first thing to check while you are looking for a PCB repair service is their call center facility. To answer the calls, clear the customer queries, support personnel of virtual centers must be available all the time. And the customers should never know they are approaching the third party.

Utilization of supply lines

Do you know the biggest challenges in post sale fulfillment in production overseas? It is the use of supply lines. It is quite difficult to find the foreign manufacturing to make sure the correct parts are always used without mentioning the issues that keep counterfeits at bay. Besides that if the equipment is defective, you may have to wait for long months to get the replacement products. Thus transportation can be hectic in order for a speedy response.

Lack of diagnostics at component level

Offshore production of small components is really tough and companies don’t try to repair at component level. Instead they try to change the entire product or device as they lack the enough facilities to repair the bad component properly. The real cost effectiveness of foreign manufacturing with a wasteful procedure is seen as the least bad choice. Whereas if the local manufacturing partner is doing the technical work, it is easy for them to do small component level diagnostics and fixation. You’ll lose a far smaller amount of money sending out replacement products that could be sold instead.

Testing And Reporting Issues

When you hire a third party service center to repair the products, you do not get any real incentive to perform at the minimum level. They do not get the sufficient information or collect the same for the problems facing them. Thus, even major issues can be hidden from you till it has become a huge issue. If your partner manufactures the products with the same components, they have every tool to identify the defects and fix it at the earliest. If the service center has the facilities online, they will be checking out the issues as soon as the customers report them. Thus you get faster product revisions that reduces the damages and unforeseen defects and cause.

Customer oriented

It is known to everyone that if your customers are happy then they will buy more products. If they buy more products, then you will have to order more from the manufacturer. An electronic assembler who checks only on quality products must be aware of this. If they are able to make customers happy then they will bring more business. In turn they get good encouragement to treat your customers well and improve your business. New clients cost 5 times more to gain as it is challenging to retain the customers. Quality customer service is a no-brainer from a long-term standpoint.

Choose your Electronics Manufacturer carefully

You really can get the best of all with the right manufacturing: Affordable high-quality electronics, with support and fulfillment services to match.If you’re still dealing with the months-long supply chains and language barriers with overseas production, Automat would be the ideal choice to help you in this regard. To learn more industrial automation companies get in touch with us.